Brief: Brainerd Chemical Company is a trusted national leader in peracetic acid (PAA) supply, helping wastewater facilities meet tightening regulatory and sustainability demands with confidence. Through strategically located production sites, rigorous quality control, and responsive logistics, Brainerd ensures reliable, high-purity PAA delivery nationwide. Its technical experts provide hands-on guidance—from pilot testing to safety and compliance—making PAA adoption seamless, efficient, and future-ready for municipalities and industrial operators alike.

Across the U.S., wastewater treatment facilities are re-evaluating their disinfection methods in response to tighter regulatory limits, sustainability goals, and safety concerns. Peracetic acid (PAA) is rapidly emerging as a preferred solution—offering powerful microbial control, minimal by-products, and simplified operations compared to traditional chlorine-based systems. This article explores why so many municipalities and industrial plants are making the switch, how PAA supports permit compliance, and how Brainerd Chemical Company is leading the way with reliable supply, technical guidance, and unmatched expertise in PAA applications.

Regulatory Pressures Are Driving Change

Tightening effluent limits and stricter NPDES permit conditions have forced utilities to reconsider their legacy disinfectants. Traditional chlorination, while effective, often produces halogenated disinfection by-products (DBPs) such as trihalomethanes (THMs) and haloacetic acids (HAAs)—compounds that are increasingly restricted due to their toxicity and persistence in aquatic ecosystems.

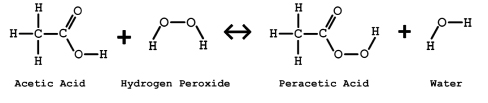

PAA, by contrast, decomposes into oxygen, water, and acetic acid, leaving virtually no harmful residuals. This makes it easier for wastewater facilities to meet evolving discharge requirements and avoid DBP-related violations.

In many states, regulators now actively encourage utilities to evaluate non-chlorine disinfection methods. PAA’s strong oxidation potential and rapid microbial kill rate make it one of the most permit-friendly options available—particularly for plants facing low toxicity limits or sensitive receiving waters.

Simplified Operations and Reduced Chemical Handling Risks

Unlike chlorine gas or sodium hypochlorite, PAA does not require specialized gas storage systems, de-chlorination chemicals, or complex feed controls.

Because it is a liquid, ready-to-use oxidant, PAA can be fed directly into existing contact chambers with minor infrastructure modifications. This simplicity translates into less operator exposure, lower capital investment, and fewer moving parts to maintain.

Facilities that transition from chlorine and sulfur dioxide systems also enjoy improved safety profiles, eliminating the hazards associated with toxic gas cylinders and leak detection systems.

Proven Performance and Flexibility Across Wastewater Types

PAA’s efficacy is well documented in both municipal and industrial wastewater systems. Its broad-spectrum antimicrobial action effectively neutralizes bacteria, viruses, and spores—even in high-solids, low-clarity, or variable-pH environments.

PAA’s disinfection mechanism is based on oxidation; it remains effective over a wide range of organic loads and maintains residual power even when other disinfectants are inhibited by ammonia or nitrogen compounds.

In addition, the fast reaction kinetics of PAA mean that many facilities can achieve target log-reductions with shorter contact times, enabling higher throughput and better operational flexibility during peak flow events.

Lower Lifecycle Costs and Fewer Permit Headaches

Although the chemical cost per gallon of PAA may initially appear higher than chlorine, the total cost of ownership often favors PAA when safety, de-chlorination, maintenance, and regulatory compliance are considered.

For example, eliminating sodium bisulfite for de-chlorination can reduce both chemical consumption and storage complexity, while minimizing operator training requirements.

Equally important: the elimination of DBPs and residual chlorine in effluent often helps facilities avoid expensive permit violations, costly remediation, or negative public scrutiny.

A Sustainable, Future-Proof Choice

Sustainability is becoming a core KPI for wastewater utilities. PAA’s eco-friendly breakdown products—oxygen, water, and acetic acid—align perfectly with green infrastructure and ESG goals.

Unlike chlorine, PAA leaves little to offers a scalable, sustainable solution that aligns with no halogenated footprint, making it the preferred option for facilities that discharge into sensitive aquatic habitats or supply reclaimed water for reuse. As utilities face increasing pressure to modernize infrastructure and minimize chemical hazards, PAA represents a scalable, sustainable solution that fits both regulatory and environmental priorities.

Meeting Compliance with Confidence

Regulatory momentum continues to build in favor of peracetic acid. State environmental agencies and the U.S. EPA are recognizing its potential as a safe, effective alternative that meets both microbial and toxicity standards without contributing to chlorinated by-products.

For municipalities preparing for permit renewals or plant upgrades, now is the time to evaluate pilot testing and document performance data. Early adopters have already demonstrated reliable disinfection performance across a variety of wastewater matrices, paving the way for broader regulatory acceptance nationwide.

Brainerd Chemical Is Your Trusted PAA Supply Partner

When reliability, regulatory expertise, and on-time delivery matter most, Brainerd Chemical stands as the nation’s benchmark for peracetic acid (PAA) supply and support. With more than a century of chemical manufacturing experience and one of the industry’s most robust distribution footprints, Brainerd Chemical delivers consistency, safety, and performance that utilities can depend on.

From production through delivery, every stage of Brainerd’s PAA program is designed for quality assurance and continuity of supply. The company’s strategically located facilities—including regional production and transloading hubs—allow rapid fulfillment to wastewater treatment facilities across the U.S., minimizing lead times and transportation costs. Advanced storage, blending, and packaging capabilities ensure that every gallon meets strict purity standards, backed by rigorous testing and quality control.

Beyond supply, Brainerd Chemical partners with clients to ensure successful PAA adoption and optimization. Its technical experts offer field-level assistance, pilot testing guidance, dosage calibration, safety and handling training, and regulatory compliance support—helping operators integrate PAA seamlessly into existing systems. This consultative approach ensures plants achieve consistent microbial control, predictable costs, and permit ready performance with minimal operational disruption.

In an industry where downtime is costly and compliance is non-negotiable, Brainerd Chemical’s scale, reliability, and service excellence make it the trusted PAA partner for municipalities and industrial operators nationwide.

A Stronger Tomorrow Through Smarter Wastewater Treatment

Peracetic acid (PAA) represents a decisive step forward for organizations interested in advancing sustainability, protecting operators, and safeguarding communities. By eliminating halogenated by-products, reducing chemical handling risks, and simplifying compliance, PAA helps facilities operate more safely and sustainably while maintaining exceptional microbial control.

For utilities facing aging infrastructure, tighter permit renewals, or public pressure to reduce risks, PAA offers a future-proof path that aligns operational efficiency with environmental responsibility. Facilities that make the switch gain more than just regulatory peace of mind—they gain operational resilience, community trust, and a disinfection strategy built for tomorrow’s standards.

With Brainerd Chemical as a supply partner, wastewater operators can count on reliable delivery, deep technical support, and industry expertise that turns the promise of PAA into real-world performance. Together, these advantages make PAA not only a better disinfectant, but a smarter investment in the future of clean water.

About Brainerd Chemical Company

Brainerd Chemical Company is one of the nation’s leading chemical manufacturers and distributors, supporting industries from energy and agriculture to water treatment and manufacturing. We combine proven expertise with innovative packaging, logistics, and service solutions to help our partners achieve efficiency, safety, and long-term success.